The Critical Role of Precision Surface Finishing in Modern Manufacturing

In today’s competitive manufacturing landscape, where components must not only perform flawlessly but also meet demanding aesthetic and durability requirements, precision surface finishing stands out as a crucial process. From aerospace to electronics, automotive to medical devices, the surface finish of a part can directly impact its functionality, longevity, and consumer appeal.

This article delves into the world of precision surface finishing, exploring what it entails, why it’s essential, the various methods involved, and how businesses can benefit from leveraging high-quality finishing services.

What Is Precision Surface Finishing?

Precision surface finishing refers to a controlled and high-accuracy process of altering a component’s surface to achieve specific characteristics. These include reduced roughness, enhanced texture, improved flatness, tighter dimensional tolerances, and improved resistance to corrosion and wear.

Unlike basic surface finishing that focuses on general polishing or coating, precision surface finishing is applied where exact specifications are critical. Think of engine components, semiconductor parts, surgical instruments, or aerospace fasteners—these items cannot tolerate surface inconsistencies.

Why Surface Finish Matters

Even minute imperfections on a part’s surface can compromise its functionality. In industries like defense or aerospace, a tiny flaw can result in catastrophic failure. In electronics, a rough contact point may lead to signal disruption. This is where precision surface finishing becomes indispensable.

Here’s why:

- Functional Efficiency: Proper finishes reduce friction between moving parts, leading to smoother operation and reduced wear and tear.

- Enhanced Durability: Surface treatments such as hard coatings or anodizing help protect the part from environmental degradation.

- Aesthetic Value: Especially in consumer goods, a refined finish elevates product appeal.

- Improved Safety: In medical devices, precise surface finishing eliminates burrs and rough edges, minimizing risks during use.

- Better Assembly Fit: Precise finishes enable parts to fit tightly and accurately in assemblies, reducing manufacturing errors.

Key Techniques in Precision Surface Finishing

Multiple processes are used to achieve a precision surface finishing based on the component material, required tolerance, and application. Here are some of the most common:

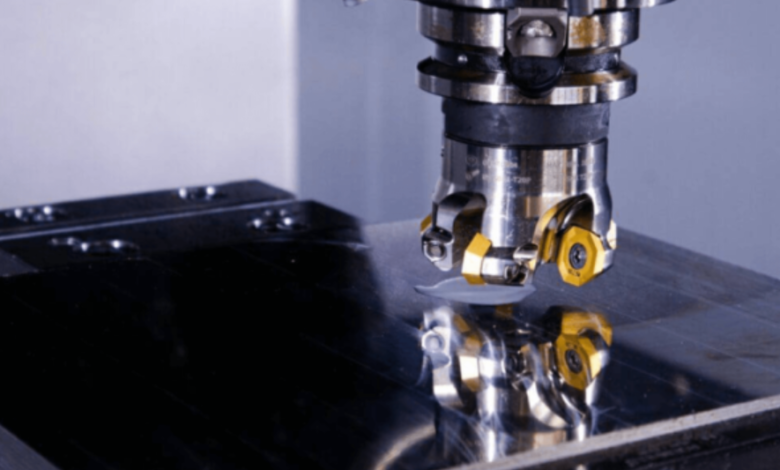

1. Grinding

Grinding is one of the most common precision finishing methods. It removes small amounts of material using a rotating abrasive wheel, producing highly accurate flatness and tight tolerances.

2. Lapping

Lapping uses a slurry of abrasive particles on a soft surface to polish parts. It is ideal for achieving mirror-like finishes or fine flat surfaces in optics, seals, and engine parts.

3. Honing

This technique involves an abrasive stone or stick that improves the geometry and surface texture of cylindrical components, like hydraulic cylinders and engine bores.

4. Superfinishing

Often used after grinding, superfinishing uses fine abrasive tools to reduce roughness to extremely low levels, improving component life and functionality.

5. Electropolishing

This electrochemical process smooths and brightens metal surfaces, especially stainless steel, by removing a thin layer of material. It’s widely used in the medical and food processing industries.

6. Chemical Mechanical Polishing (CMP)

Popular in semiconductor manufacturing, CMP combines chemical and mechanical actions to achieve atomic-level surface flatness.

Industries Benefiting from Precision Surface Finishing

Aerospace

In aerospace, where every component faces extreme stress and temperature changes, precision surface finishing ensures that surfaces are smooth, durable, and resistant to fatigue and oxidation.

Automotive

Engine parts, gear systems, and fuel injectors must operate under tight tolerances. Precision finishing improves their performance and lifespan.

Medical Devices

From surgical scissors to orthopedic implants, the medical field demands surfaces free from contamination, burrs, and roughness.

Electronics

Printed circuit boards (PCBs), connectors, and sensors benefit from finishing processes that enhance conductivity and prevent corrosion.

Tool & Die Manufacturing

In dies and molds, precision finishing reduces friction, helps in demolding, and extends the tool’s working life.

Measuring Surface Finish: Ra, Rz, and More

To ensure quality, manufacturers use parameters like Ra (Roughness Average) and Rz (Mean Peak-to-Valley Height). Advanced surface profilometers and optical measurement tools assess these parameters to verify that components meet the defined specifications.

Maintaining consistency in precision surface finishing requires real-time monitoring and feedback during the finishing process, which modern automated systems can now perform with exceptional accuracy.

Challenges in Precision Surface Finishing

While it’s crucial, precision finishing is not without its difficulties:

- Material Sensitivity: Some metals like titanium or magnesium require specialized techniques to avoid damage.

- Cost and Time: High-precision processes are often more time-consuming and expensive than standard finishing methods.

- Skilled Labor: Operating high-end finishing machines or conducting manual precision finishing demands skilled technicians.

- Consistency: Achieving repeatable results across thousands of units requires stringent quality control.

Despite these challenges, the advantages of precise finishing far outweigh the costs, especially when product performance and customer satisfaction are at stake.

Choosing the Right Precision Surface Finishing Partner

When outsourcing or investing in a precision surface finishing service, consider the following:

- Experience and Specialization

Look for providers with a proven track record in your specific industry. Finishing requirements vary greatly across sectors. - Advanced Equipment

Precision demands advanced CNC grinding machines, polishing equipment, and measurement systems. Ensure the provider uses updated technology. - Quality Control Measures

Certifications like ISO 9001 or AS9100 reflect a company’s commitment to consistent quality. - Customization Capabilities

The provider should offer tailored solutions based on material type, finish requirements, and volume. - Turnaround Time

Precision should not mean delay. Look for efficient workflows and rapid delivery without sacrificing quality.

Future of Precision Surface Finishing

Technology continues to transform this niche field:

- Automation and AI: Intelligent systems now optimize finishing sequences in real-time, reducing waste and improving consistency.

- Additive Manufacturing Integration: 3D-printed parts often require surface finishing; hybrid post-processing is being developed for these new applications.

- Eco-Friendly Solutions: Water-based, solvent-free, and energy-efficient finishing processes are gaining traction to reduce the environmental footprint.

Conclusion

Whether you’re producing intricate aerospace components or precision medical implants, precision surface finishing is the final and crucial step that ensures optimal function, safety, and aesthetic quality. It’s not just a technical process—it’s a value-add that reflects your brand’s dedication to excellence.

Investing in the right finishing method and partner is key to staying ahead in today’s fast-moving manufacturing environment. After all, in many industries, it’s not just about what’s under the surface—it’s about how the surface is perfected.